We deliver peace of mind

What is CES

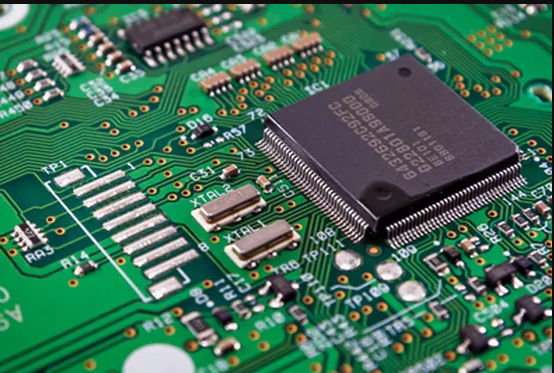

Our Specialty

We are specialised in the area of intelligent embedded design and electronic manufacturing.

Our strength

Our core strength is in leveraging the latest technologies to achieve the goals of our clients. We are constantly updating our knowledge and building valuable skills to deliver high end service to you. Continuous improvement is an integral part of our professional practice. Our core values are based on high ethical standards, customer loyalty, dedicating ourselves to deliver the best results to our clients, personal integrity, treating everybody with respect, honor and dignity and creating an environment that promotes high levels of understanding, synergy, cooperation and productivity.

Our Services

We offer flexible services that meet clients needs, nothing is too small or too big. We offer plans and packages based on agreed upon tasks including per meeting, per training, per coach, per day, per review, per issue solved, per week, or per project. Other plans can also be discussed and delivered upon request.

Our Experience

We have been actively productive in this industry for over two decades designing, building, testing, sourcing, serving, coaching, training, and taking ideas from drawing board to production.

We offer the following services:

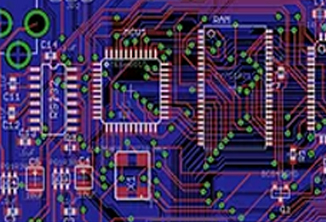

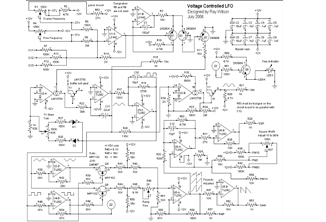

Engineering Design Support:

New product design, Test Fixture Design, Automatic Testing, Electro mechanical, Interface, Hardware, Software, and Firmware.

Engineering Documentation:

Product Specifications, Package Specifications, Theory of Operation, Schematics, Flowcharts, and Engineering Drawings.

Engineering Communications:

Facilitating communication between team members, reporting to management, coordinating between team members and management, brainstorming ideas, Engineering Presentations, supporting new Inventions, conducting Mastermind meetings, conducting Engineering Design Review, Production Review, Testing Review, Project Planning, interviewing and testing new candidates before recruiting them, Team Leading, coaching / mentoring team members, customer support, searching for suppliers and coordinating purchases.

Engineering Training:

Training new employees and team members, briefing managers, and customer training.

Team Coordination:

assigning tasks based on team member strength, supporting team planning, coaching team members on issues inside or outside work place, guiding team members to the proper resources they need to achieve the company goal, swapping team members roles when proven to be productive, searching for additional resources based on project requirement and work load, and notifying management about results based on agreed upon measures.

Product Integration:

Integrating new feature to an existing product, integrating a product to another product, integrating hardware and software, and integrating peripherals with a product.

Electronic Lab Support:

Designing and building new modern lab from scratch (all sizes depending on projects and needs), sourcing for new (or used) lab equipment, tools, safety and security equipment, machines, furniture, services and parts (electrical & electronic & chemical & mechanical).

Sustaining Engineering:

We take care of product matters from second sourcing, component replacement, re-designing, sustaining old products, serving and refurbishing, troubleshooting, and conducting product review, performance, and Root Cause Analysis (RCA).

Sourcing:

making smart search for the product parts including electrical, electronic and mechanical, for use in prototyping and production, that meet engineering standards and product requirement, RoHS compliant parts and that which meet product End Of Life (EOL) criteria, and creating innovative robust design patch that speeds up the launch of Beta, or old products, under sustaining service.

Inspection:

We inspect intermittent, or persisting, issues and find the cause of defect, smoke, malfunction, and breakage. We save new products from death bed. We can identify if the effect is originated from malpractice, negligence, natural or accidental cause and recommend, implement, reliable solution to prevent failure from happening again.